Ningbo Sunyer Machinery Co., Ltd.

METAL PRODUCTS

CATEGORY

STAMPING

Metal Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Stamping is usually done on cold metal sheet.

How to choose the best metal stamping material for your products?

Steel

Steel is a dense, highly durable metal alloy known for its inherent strength and design flexibility. Due to the presence of iron, steel and most steel alloys also exhibit magnetic properties. Benefits of steel include:

a. Versatility. Although steel is an alloy itself, it can also be combined with other alloying elements in varying proportions to create materials with enhanced mechanical properties.

b. Excellent formability. Steel parts are compatible with a wide range of metal forming processes, including stamping, machining, cutting, forging, welding, and more. This gives manufacturers the flexibility to create a range of intricate or unique metal products.

c. Affordability. Steel and steel alloys are some of the most cost-effective material options for stamped parts since they are easy to source and highly compatible with most metal forming processes.

Stainless steel

Stainless steels are iron-based alloys with various proportions of chromium in their composition. Although they tend to be more expensive than carbon steels, their superior engineering and mechanical properties justify their higher costs for certain applications. Benefits include:

a. Corrosion resistance. Due to the presence of chromium in their composition, stainless steels outperform most carbon steels in terms of corrosion resistance. This makes them a popular material choice for medical and food handling applications. Carbon steels generally require galvanization to provide similar levels of protection against corrosion.

b. Attractive finish. Stainless steels provide parts with a smooth, lustrous surface that is easy to clean and maintain.

c. Magnetism. Stainless steels are available in both magnetic and nonmagnetic options depending on their microstructure and composition.

Brass

Brass is an alloy consisting of copper and zinc in varying proportions. Known for its hardness and malleability, brass is suitable for everything from stamped medical components to locks, bearings, valves, and gears. Benefits of brass include:

a. Thermal and electrical conductivity. As a copper-containing alloy, brass exhibits excellent thermal and electrical conductivity.

b. Decorative appearance. Brass provides a characteristic bright, golden appearance, making it a popular material choice for creating ornamental hardware and other stamped components where visual appeal is a priority.

c. Versatility. Brass is ductile, corrosion-resistant, non-magnetic, and exhibits excellent acoustic and antimicrobial properties. This versatility allows brass to fulfill a range of unique material requirements.

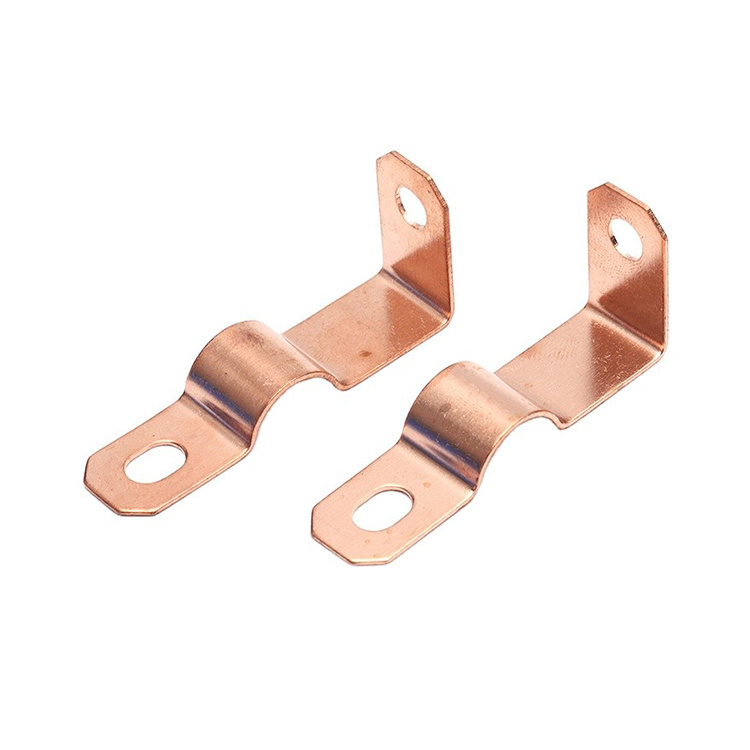

Copper

Copper is a soft, malleable metal that can be stamped in its pure form or combined with various alloying elements to create stamped parts with a range of unique properties. The most common copper alloys include bronze, brass, and nickel silver, all of which can be formed into various shapes to fit specific application requirements. With this versatility, copper and its alloys have become some of the most popular materials for metal stamping. Other benefits of copper-based materials include:

a. Corrosion resistance. Copper and its alloys are known for their exceptional corrosion resistance, which comes from the naturally protective film on their surface that reforms after the stamping or finishing process. While all copper alloys provide some degree of protection against corrosion, some are more resistant than others.

b. Decorative appeal. Copper alloys are valued for their attractive golden, amber, and yellow tints, making them a suitable option for decorative parts or architectural accents.

c. Ductility. With their excellent ductility, copper and its alloys can easily be formed into wires, metal threads, and other thin, intricate components.

d. Easy to sanitize. Copper-based materials combine corrosion resistance with a smooth surface finish, making them an excellent choice for creating parts with hygienic, easy-to-clean surfaces.

Copper also exhibits antimicrobial properties, making copper-based materials ideal for medical and food processing applications.

Beryllium Copper

Beryllium copper is a non-ferrous copper alloy often used to create springs, aircraft engine parts, bearings, and other stamped parts that must endure heavy loads or high stress. Advantages of beryllium copper include:

a. High electrical conductivity

b. High-to-moderate strength alloys

c. Corrosion resistance

d. Great thermal conductivity

e. Compatible with precipitation hardening

f. Inherent resistance to stress relaxation

Phosphor Bronze

Phosphor bronze is a copper alloy containing varying proportions of tin and phosphorous. The presence of phosphorous gives this alloy excellent fluidity in its molten state, enhancing its castability. Phosphor bronze also has desirable mechanical and chemical properties, providing stamped parts with high resistance to fatigue, wear, and corrosion.

Aluminum

Aluminum is a soft, silvery-white metal known for its high strength-to-weight ratio. This makes aluminum and its alloys well-suited for creating lightweight stamped components that still offer high levels of strength and stability. Other benefits include:

a. Excellent formability. Aluminum is extremely flexible and malleable, allowing it to be bent, stretched, hammered, and stamped into various shapes without breaking.

b. Thermally and electrically conductive. Aluminum and its alloys are effective thermal and electrical conductors, exhibiting minor resistance or energy loss in the process.

c. Resilient. Resistant to both corrosion and low temperatures, aluminum-based materials maintain their resilience in environments where other alloys would become brittle.

d. Attractive finish. Aluminum metals provide a naturally smooth and shiny surface that is easy to clean and maintain.

Titanium

Titanium is a low-density, high-strength specialty material used extensively in demanding aerospace, nuclear, marine, and energy applications. Titanium alloys can withstand some of the most aggressive and extreme environments, but their strength and hardness can make stamping and other metal-forming processes challenging. They also tend to be more expensive than other alloys due to the complex process required to produce titanium.